Portfolio for AAC Plants

Machinery for your AAC Factory

Our machines are sturdy and reliable – created to budget and on schedule. They are constantly doing their job to manufacture AAC blocks and panels in a consistent quality – from the mixing and dosing, the fermentation process, the cutting, autoclaving until the packaging of the finished products.

Sand Processing and Storage

- Design and engineering of raw material processing including pumps, sand ball mills, slurry tanks with integrated stirrers and other material handling equiment

- Assembly and commissioning of these components

- Control system

Dosing and Mixing System

- Design and engineering of the complete mixing tower

including silos, scales, screw-conveyors and agitators - Assembly and commissioning of these components

- Control system

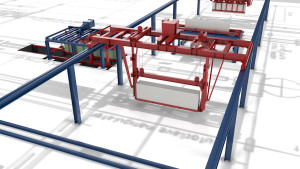

Circulation of Hardening Plates and Moulds

- Design and engineering of the circulation system

- Transport manipulators (tilting crane, autoclave crane, unloading crane, reinforcement crane for panel production)

- Transfer tables

- friction-wheel drives

- Moulds, hardening plates and curing cars

- Mould cleaning, mould oiling

- Cleaning of hardening plates

- Track systems with friction-wheel drive

- Control system

Cutting Line

- Design and engineering of the cutting line including pre-cutting plant, longitudinal cutting plant, tongue and groove profiling station, grip hole mill

- Transportation of green broke to the return slurry tank including stirrers

- Control system

Controls of the Autoclaves

- Design and assembly of new controls

Packaging

- Design and assembly of new plants including machines for packaging with stretch foil or shrinkage foil, labelling printer and dispensers, inkjet printers

- Control system

Option 1 (Finishing of AAC wall panels, floor and roof panels and other reinforced elements / lintels)

- Consultancy and design of reinforcement machinery

- Straighteners and cutting machine for wire bars

- Mesh welding machines

- Mesh cage welding machine

- Cross bars and needles

- Control system

Option 2 (Finishing of AAC wall panels, floor and roof panels and other reinforced elements / lintels)

- Consulting and design of finishing centers

- Automatic sawing lines

- Control system

Option 3: (Finishing AAC blocks)

- Consultancy and design of finishing centers for U-blocks and lintels

- Automatic sawing lines for U-blocks and lintels

- Control system